This website uses cookies to ensure you get the best experience on our website. Read more

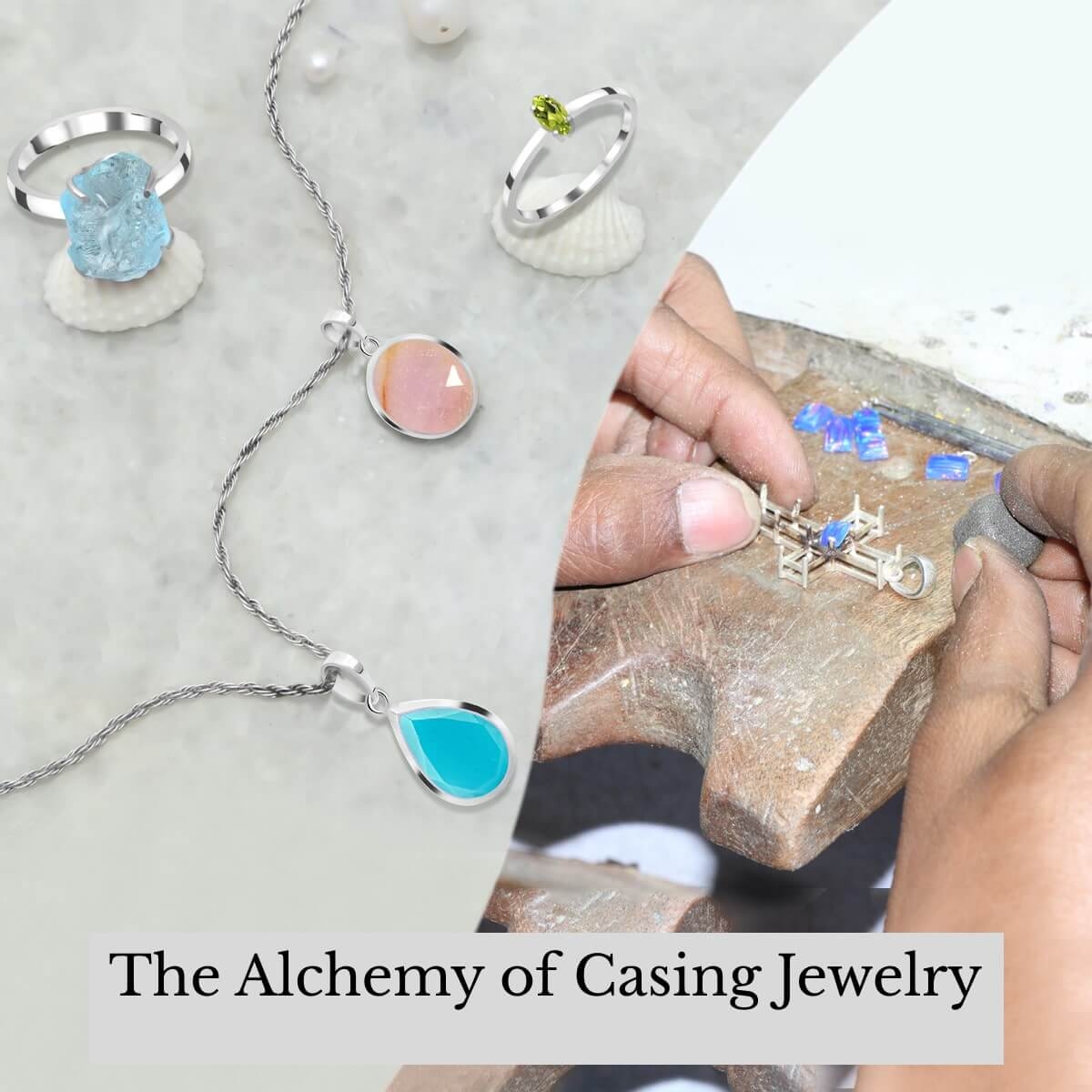

Casting Jewelry: Sculpting Artistry into Wearable Masterpieces

May 24, 2024

Jewelry has always been something past an extra; it reflects culture, history, and individual articulation. From old urban foundations to current societies, Jewelry has an enormous spot in human frivolity and symbolism. Furthermore, the specialty of making and casting Jewelry is a fascinating and complex cycle used to make delightful adornment pieces. It incorporates changing fluid metal into an ideal shape using a mold. This method has been utilized for a long time and has been created with progressions in innovation and materials.

History of Casting Jewelry

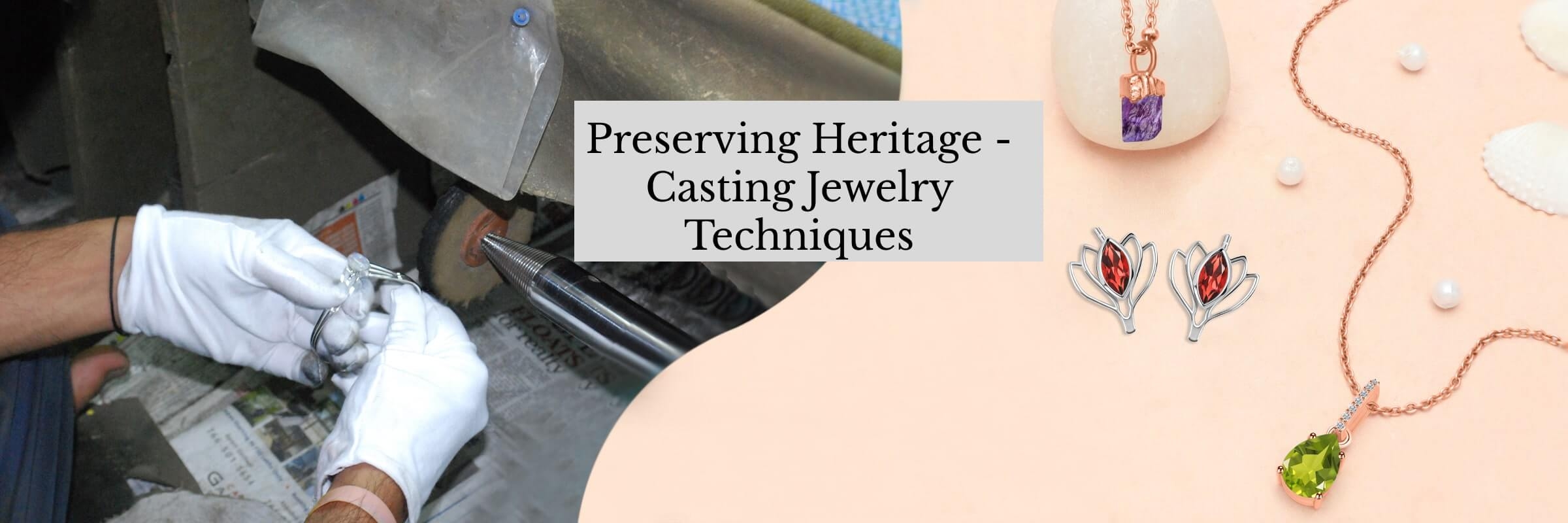

The craft of making and Casting Jewelry can be followed back millennia. Old civic establishments like the Egyptians, Greeks, and Mesopotamians were capable of metalworking and projecting strategies. They made jewelry pieces using lost-wax casting techniques, where a model of the frill piece was carved in wax, shrouded in soil and warmed to break up the wax away, leaving an empty shape. Fluid metal then, at that point, filled the shape, making the final jewelry piece.

The significance of accessories during these times extended past simple style; they held strict, social, and agent importance. For example, old Egyptian enhancements frequently combined complex plans and gemstones like turquoise, moonstone, larimar, and so on to address strict divinities, monetary prosperity, and affirmation in life following death.

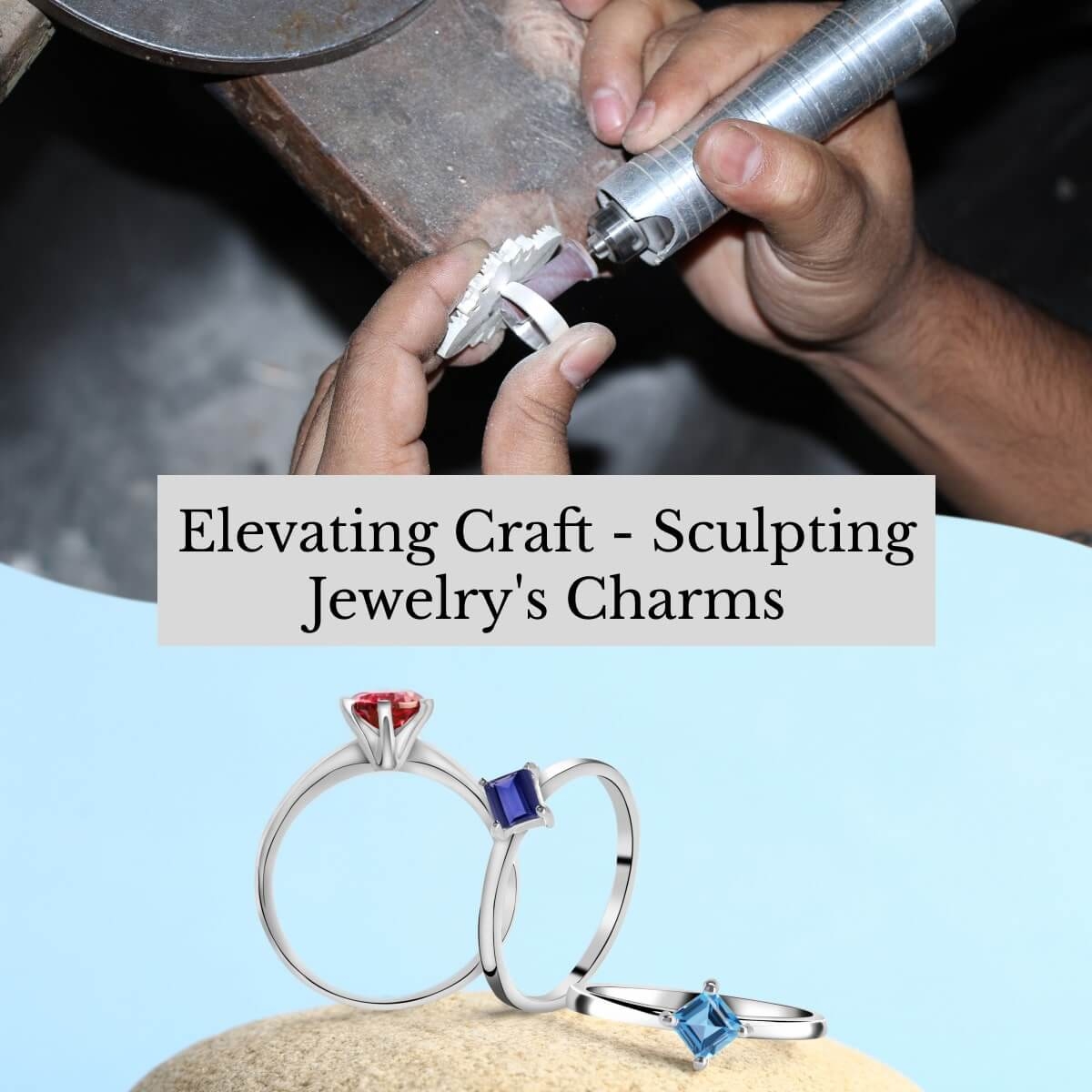

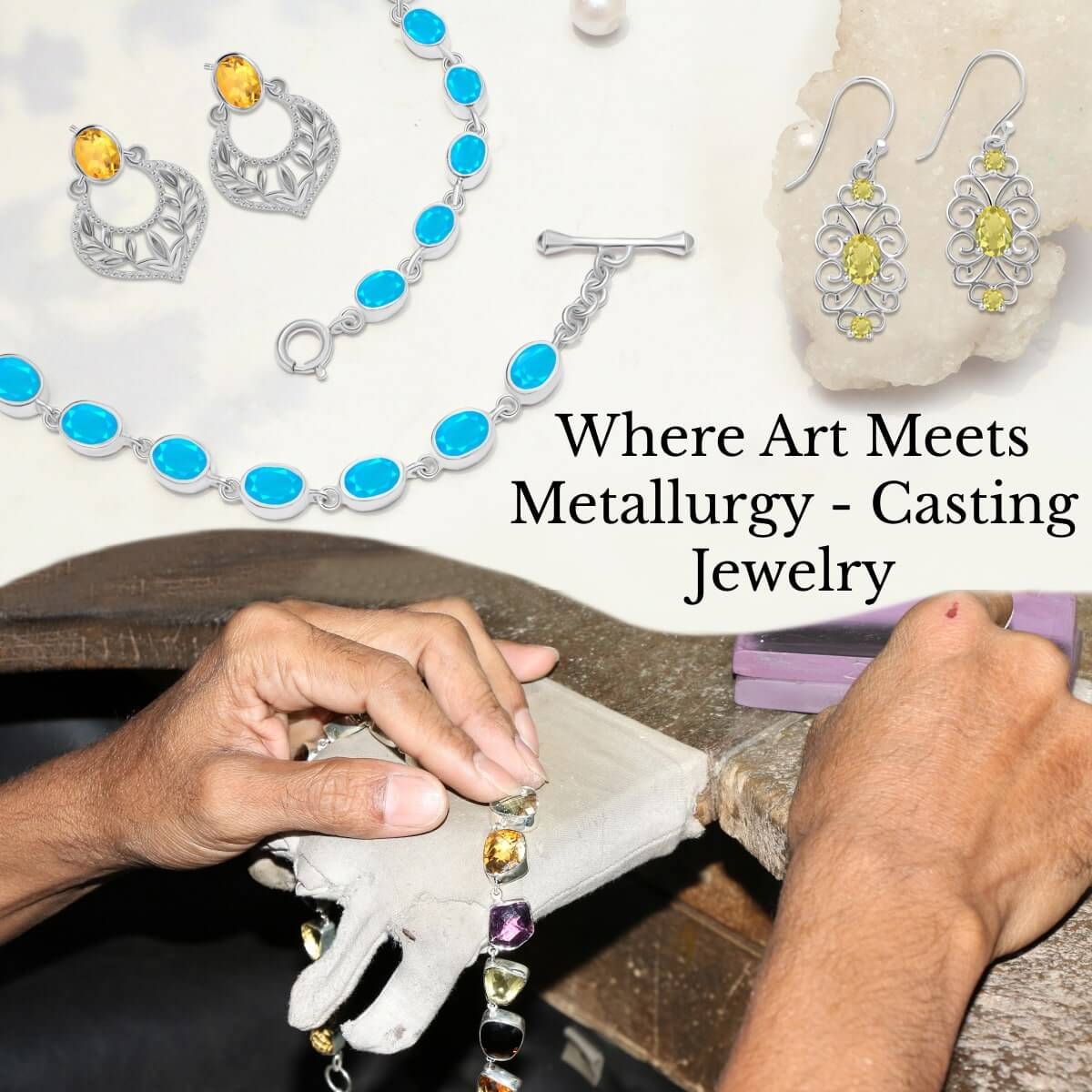

Sculpting Artistry in Jewelry Design

At the center of Casting Jewelry lies the artistry of jewelry design. The gems planner's responsibility is to conceptualize and picture the piece, changing thoughts into significant plans. Their imaginative capacity grants them to shape special and enamoring shapes, designs, and subjects, carrying life to the last magnum opus. The adornments configuration process begins with portraying, where the specialist draws their vision on paper. This underlying step incorporates a creative mind, an innovative brain, and a profound comprehension of plan parts like equity, equilibrium, and extent. The planner's ability to consolidate these parts into an amicable creation permits the projecting system.

When the sketch is done, current advancement turns into the most basic variable with the programming guide of the PC-upheld plan (PC-supported plan). Gems fashioners use PC-supported plan devices to refine their contemplations, make 3D models, and animate how the piece will search in different materials and sizes. Blending conventional imagination with mechanical movements has adjusted the gem's configuration process, considering more prominent exactness and experimentation.

Traditional Methods of Casting Jewelry

A. Lost-Wax Casting

The lost wax casting interaction, or investment casting, stays one of the most broadly involved strategies for complex projecting gems pieces. While the technique has progressed long term, the center standards continue as before:

Wax Cutting: The process of casting Jewelry begins with wax cutting, where talented artisans shape and specialty wax into charming plans, consolidating fine subtleties and fragile components.

Mold Making: When the wax model is done, it is encased in a shape-making material, similar to mortar or hypothesis, to frame the external mold.

Burnout: The mold is then warmed to relax and eliminate the wax, leaving an empty cavity that will later be loaded with fluid metal.

Casting: Fluid metal, regularly gold, silver, or platinum, is filled the depression, assuming the type of the first wax model.

Wrapping Up: After the metal has cooled and solidified, the piece goes through finishing processes, such as cleaning, welding, and stone setting, to achieve the final piece of Jewelry.

B. Sand Casting

Rather than lost-wax casting, sand casting is a less mind-boggling methodology. A mold is created utilizing a compacted sand blend, and fluid metal is discharged straightforwardly into the sand cavity. Albeit less itemized than lost-wax casting, sand casting considers more critical gem pieces, often with a crude and regular style.

C. Centrifugal Casting

This technique uses radiating power to disperse fluid metal similarly inside a mold. The mold is turned rapidly on its pivot, ensuring the metal arrives at all of the subtleties of the shape, achieving a more uniform casting.

D. Vacuum Casting

Vacuum Casting purposes a vacuum to bring the fluid metal into the mold. The air is dispensed from the shape pit, making a strain qualification that maneuvers the metal into the mold.

Modern Method of Casting Jewelry

A. Innovation and Computer-Aided Design

PC Upheld Plan (PC Supported Plan): As of late, development has transformed the casting jewelry process utilizing PC-helped plan to program. Gems planners can now make careful and versatile 3D models on a PC.

3D Printing: PC-helped plan models can be changed into genuine wax models using 3D printers, accelerating the planning stage and considering more prominent trial and error with complex structures.

B. Contemporary Materials

Past Conventional Metals: While gold, silver, and platinum remain staples in casting Jewelry, present-day artisans investigate new materials, including titanium, treated steel, and various mixes, to develop their creative likely results.

Gemstones and Elective Materials: jewelry experts incorporate gemstones like Opal, Citrine, emeralds, valuable stones, pearls, and groundbreaking materials like wood, earthenware production, and sap, adding profundity and uniqueness to their plans.

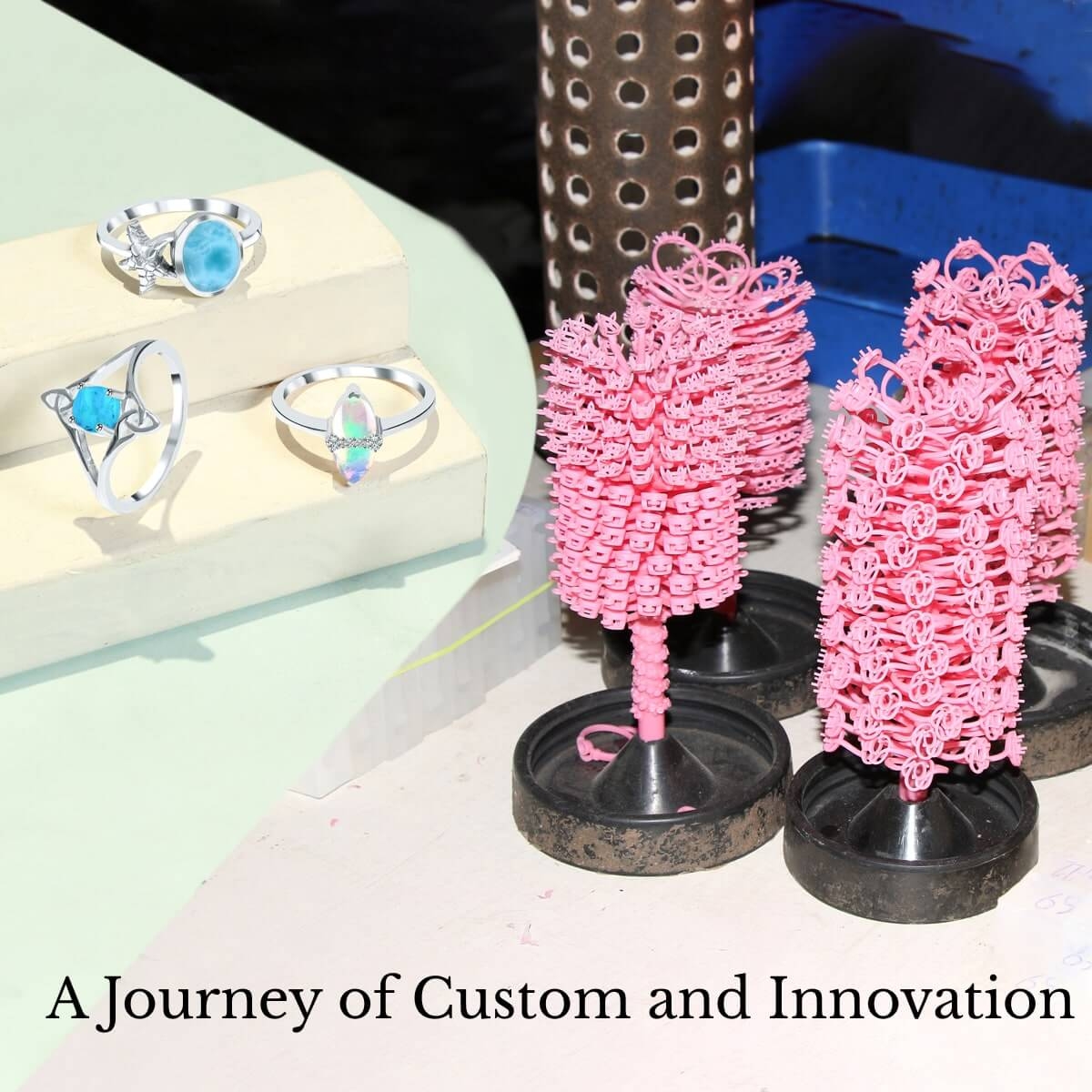

Custom and Innovation at a Crossroads

While advancement has conveyed surprising movements in casting Jewelry, it is pivotal to perceive that the masterfulness in casting Jewelry isn't solely dependent upon the devices utilized yet on the creative vision of the skilled worker. However, a specialist gem expert's mastery lies in something beyond understanding the casting system, blending their manifestations with their extraordinary imaginative articulation.

The trade between custom and development is best exemplified when trained professionals and craftsmen use present-day instruments to strengthen conventional techniques. For instance, mechanized plan gadgets and 3D Printing outfit experts with new streets for experimentation and grant them to drive the limits of their innovativeness further.

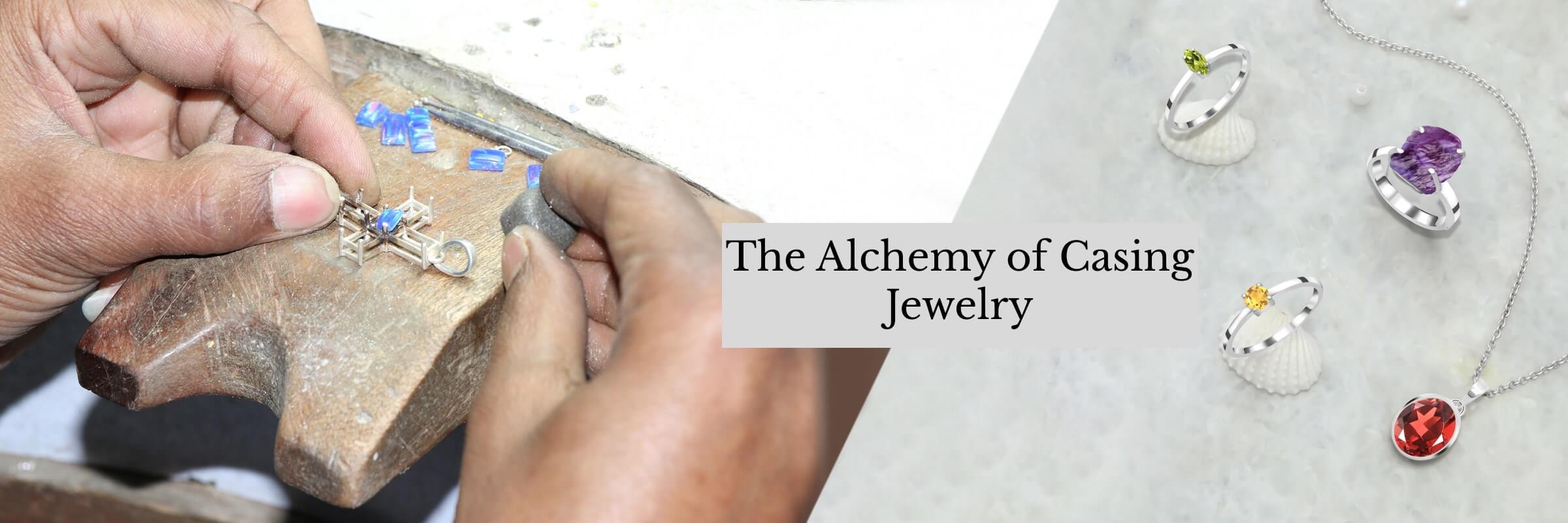

Materials Used in Casing Jewelry

Valuable Metals: The most notable metals in casting Jewelry are 925 Sterling silver, gold, platinum, plain silver, and palladium. Each metal offers remarkable properties concerning assortment, strength, and worth, putting them on the map for assembling fine Gems.

Base Metals: Base metals like copper, metal, and bronze are used in casting Jewelry. They are utilized now and again for ensemble gems or as blends to work on the properties of valuable metals.

Gemstones: Gemstones, similar to Swiss blue topaz, rhodonite, garnet, ruby, sapphire, and emeralds, are regularly incorporated into jewelry designs to add tone, sparkle, and worth to the final piece. They can be set in the metal after casting or cast directly into the piece.

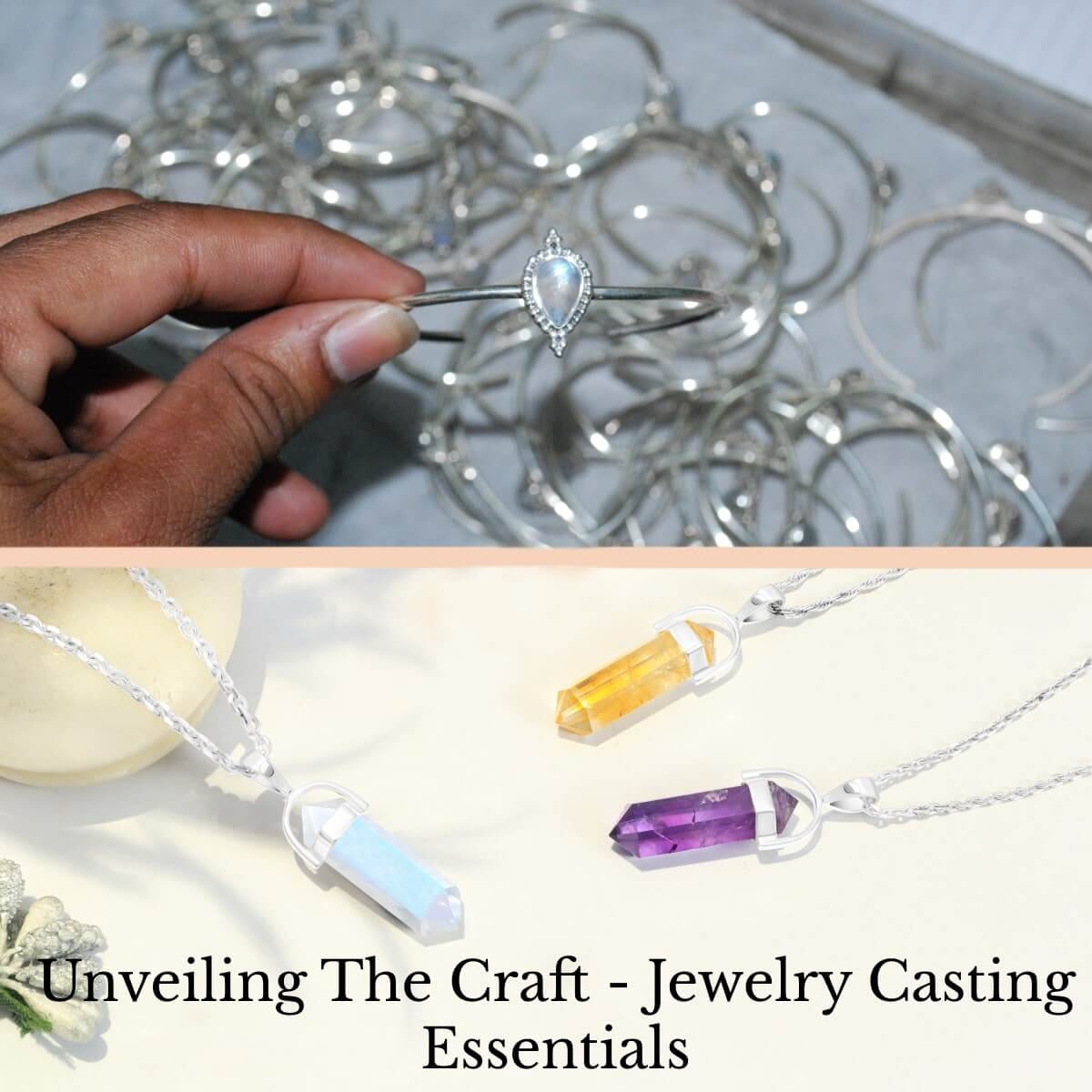

Casting Jewelry Process

A. Jewelry Designing: The interaction starts with the design of the jewelry piece, whether it is rings, bracelets, necklaces, earrings, or pendants. This ought to be conceivable using PC-upheld (PC-supported plan) programming or high-quality by gifted specialists.

B. Making the Expert Model: The arrangement is 3D printed or handled using a PC-supported plan from a block of wax or another material. When finished with the hand, the master model is carved from wax or various materials.

C. Mold Making: The master model is used to make a mold. The model is associated with a sprue in conventional lost-wax casting, outlining a tree-like development. The mold is made by incorporating the model with an unshakable material.

D. Infusing Wax: On occasion, the mold is used to inject fluid wax, making a wax impersonation of the master model. This step is fundamentally used in the jewelry industry to make different impersonations of a solitary master model.

E. Gathering The Tree: If different pieces are being projected right away, the wax duplicates are joined to a central sprue, forming a tree-like plan.

F. Investing The Mold: The wax tree or individual wax models are placed in a cup, and an unshakable material (hypothesis) is poured around them. The endeavor sets, making areas of strength for a.

G. Burnout: The cup is then warmed in an oven to wear out the wax, leaving a hole in the mold where the metal will be poured.

H. Casting: The mold is preheated, and the ideal metal or compound is melted in a cauldron. The cup is placed in a casting machine or diffusive caster, and the fluid metal is exhausted or obliged into the form.

I. Cooling and Cleaning: When the metal hardens, the cup is stifled in water, and the jewelry piece is taken out of its shape. The piece is then cleaned, wiping out any abundance of metal or blemishes.

J. Wrapping Up: The jewelry piece is cleaned, archived and may go through extra cycles like setting gemstones or plating to achieve the ideal final look.

Tools and Equipment Used in Casting Jewelry

Crucible: A crucible is a compartment to hold and disintegrate the metal in the warmer. It is made of materials that can get through high temperatures.

Heater: A radiator is used to warm the metal to its softening point. Casting Jewelry requires precise temperature control to achieve the best results.

Casting Flask: The cup is the shape wherein the speculation material is poured to make the shape for projecting.

Tongs and Gloves: Tongs and intensity-safe gloves are key for securely dealing hot metal and gear.

Casting Machine: In outward and vacuum casting, specific machines are used to turn or make a vacuum to help the casting process.

Rananjay Exports Casting Gemstone Jewelry That Transforms Artistry into Wearable Works of Art

Casting Jewelry is an old work of art that keeps developing with headways in innovation and advancement. From lost-wax casting to current 3D printing, the process has stayed an enthralling mix of creativity and specialized expertise, changing raw materials into wearable masterpieces that hold individual and social importance.

As the jewelry industry embraces moral and manageable practices, the art of casting Jewelry will continue flourishing, captivating wearers with its capacity to sculpt artistry into substantial, significant, and persevering works of wearable art. If you are also looking for a mesmerizing collection of casting Jewelry along with custom jewelry, designer jewelry, and handmade Jewelry, then you are on the correct website Rananjay Exports, a Wholesale Gemstone Jewelry Manufacturer & Supplier supplying a captivating collection of wholesale gemstone jewelry since 2013.