This website uses cookies to ensure you get the best experience on our website. Read more

Understanding Jewelry CAD Design within the Gemstone Jewelry-Making Process

December 03, 2024

An Introduction to Jewelry CAD Design and Software

Advancing technologies have transformed various industries by offering businesses the opportunity to scale rapidly as long as they provide real value. Whether streamlining the business process, enhancing customer support, or offering an online portal from where your customers can purchase, technology has impacted every sector, especially the jewelry industry. The most important contribution of technology in the jewelry-making process is jewelry CAD (Computer-Aided Designing) and CAM (Computer-Aided Manufacturing). Here, we will primarily focus on each detail related to jewelry CAD design.

Computer-aided design (CAD) software is used to create intricate models of jewelry with extremely high precision. The CAD software also enables the designer to perform rapid prototyping through 3D printing. Earlier, jewelry designs and blueprints are made manually, taking a long time. This innovation has reduced the time taken by businesses to mass-produce gemstone jewelry and sterling silver jewelry. In this blog, we will discuss the process of jewelry CAD design and other things that will clear your concept for CAD designing.

The Process of Jewelry CAD Design

Jewelry CAD design is a complex process that transforms the artistic concepts of jewelry, which is generally created through sketching manually, into a precise digital model. This enables the jewelry manufacturer to manufacture jewelry efficiently. Below are some of the steps that are involved in the process of jewelry CAD design:

- Idea Generation

The first step of any gemstone jewelry making process is idea generation. It is a step where a competent designer creates sketches or pictures that represent the exact disposition of the jewelry piece. At this stage, you establish creative directions and specifications for the gemstone jewelry that you wish.

- Digital Modeling

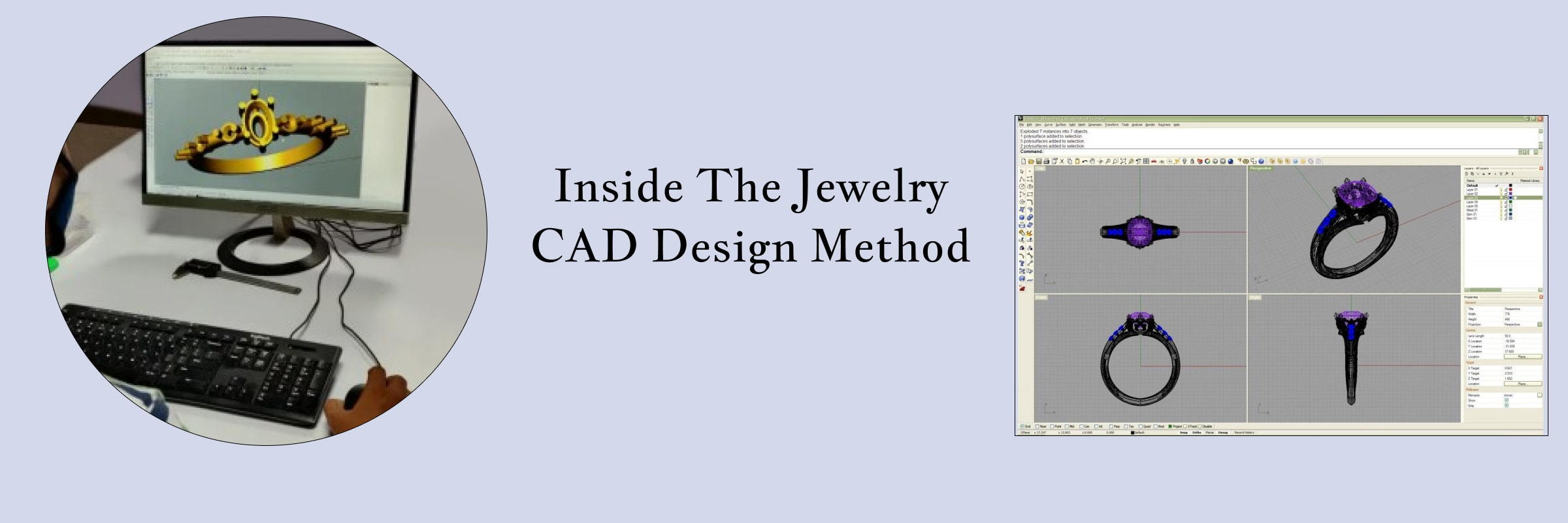

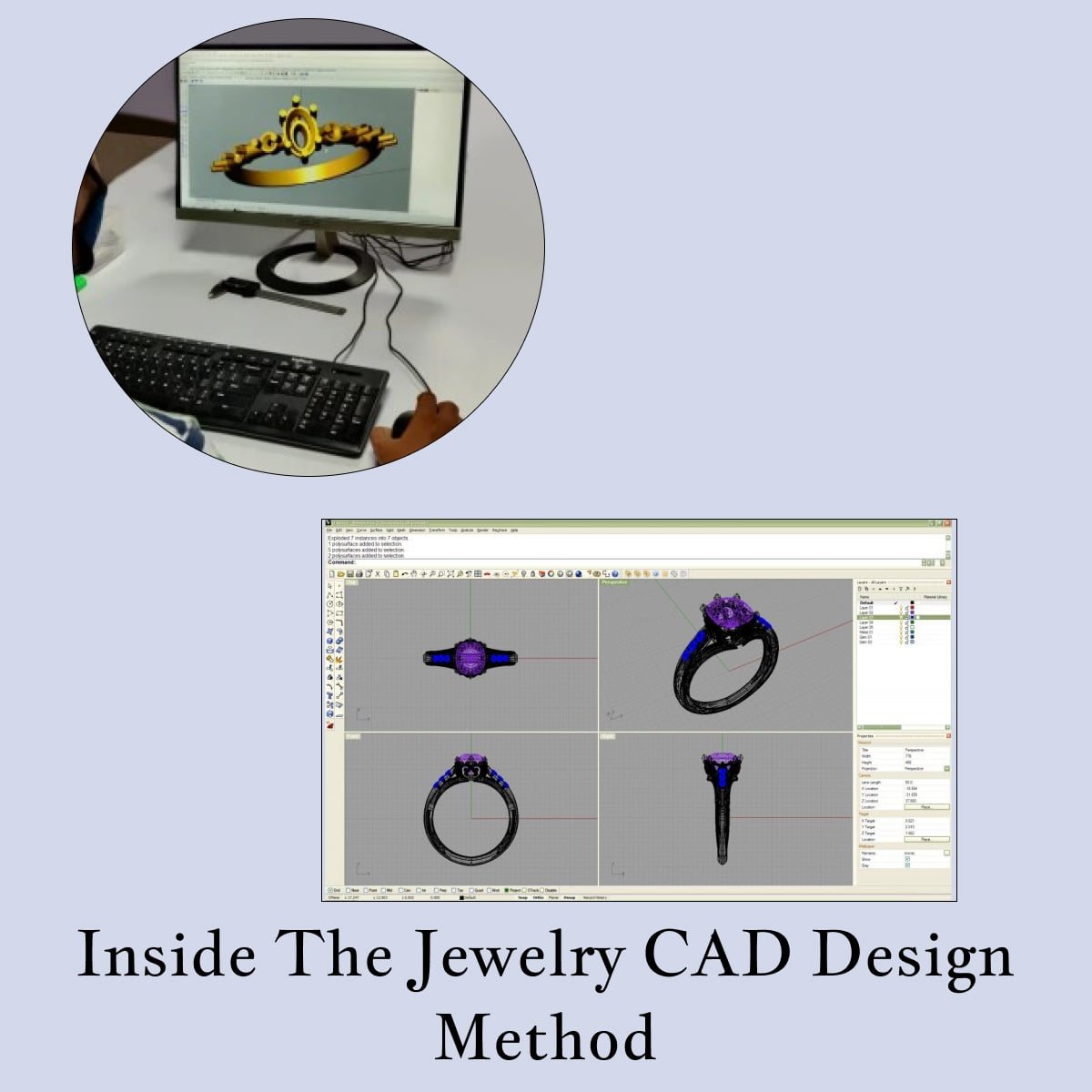

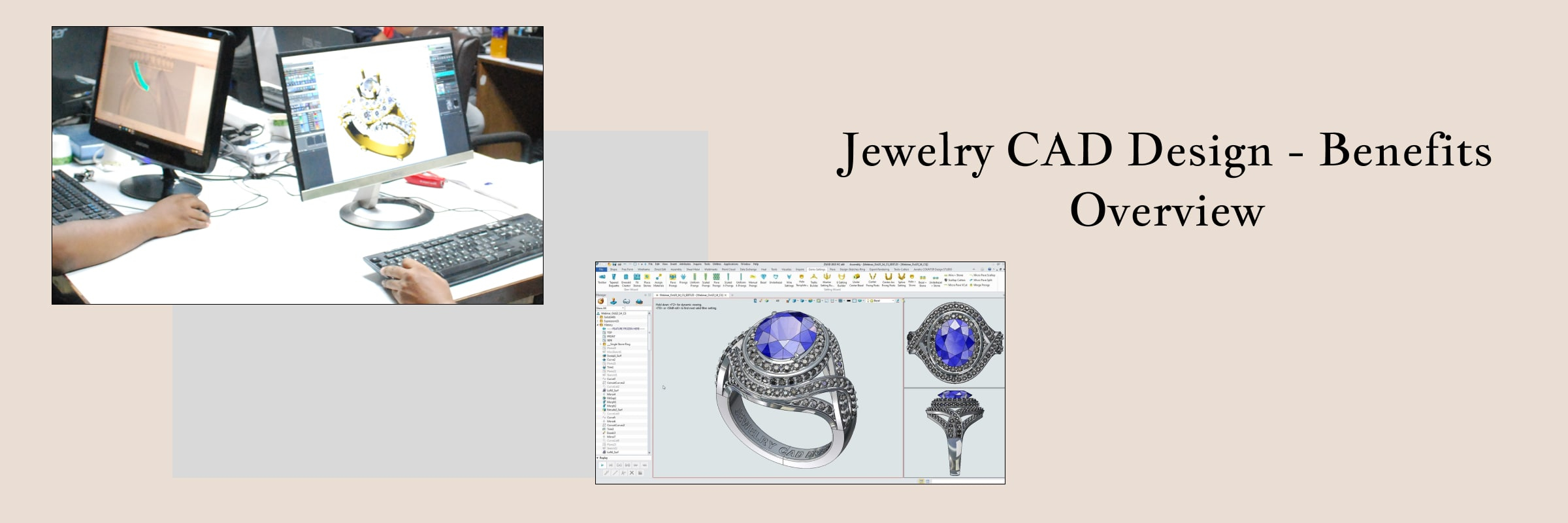

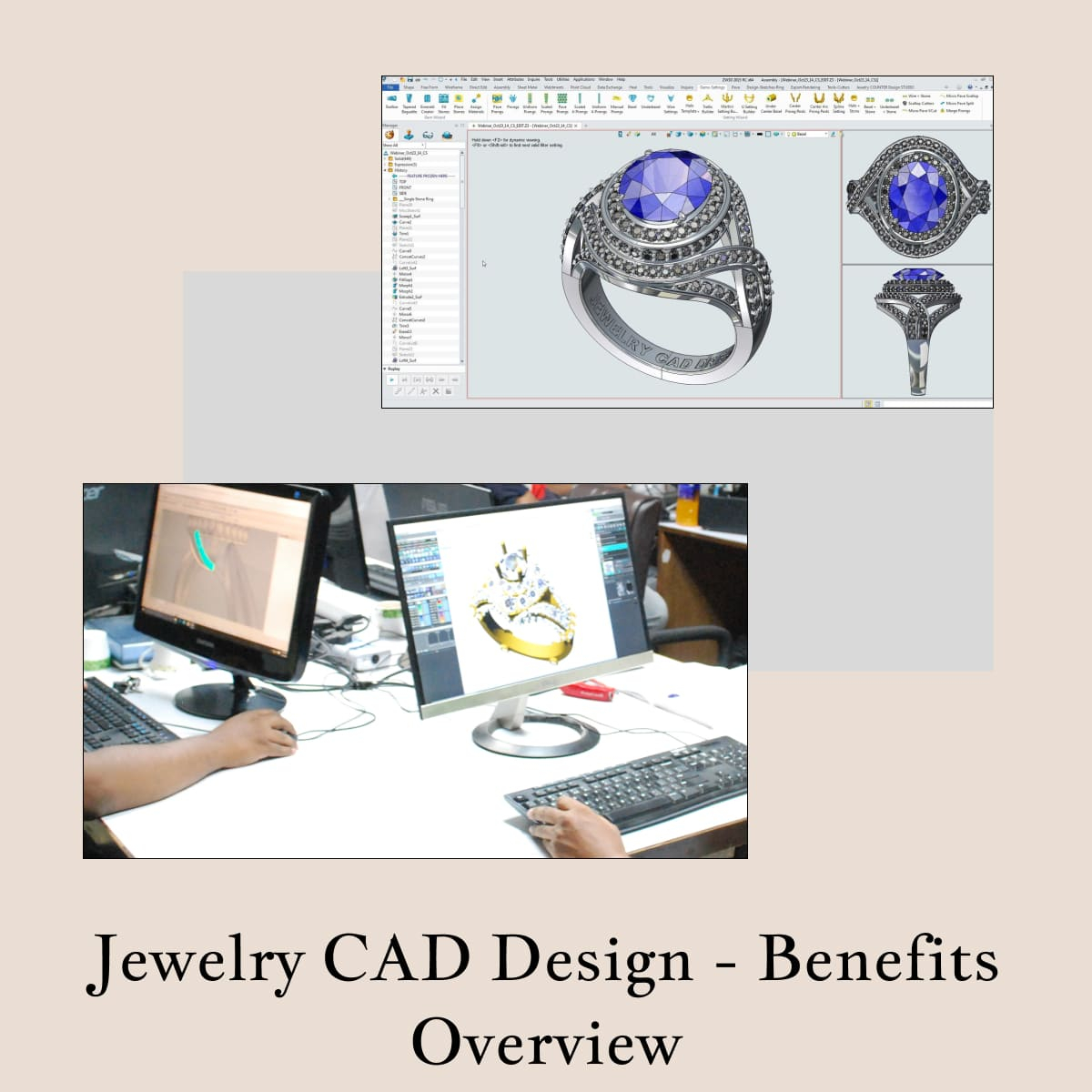

After idea generation, the designers create digital models using digital modeling tools. The process of digital modeling is the most important process of jewelry CAD design, and it is done through specialized CAD software like Rhino, AutoCAD, or Matrix. In this step, you can create digital models and 3D visualization of the model. Below is a brief description of this stage:

- Creating Detailed Models:

The designer gives input to the CAD software regarding all the necessary specifications, which include things like the dimensions, the shape of the jewelry, and aesthetic details. The sole aim of building this model is to meet the requirements that the customer expects. Because everything is done on a computer, the CAD software allows the creation of intricate designs and enables the designer to take precise measurements for the final jewelry product.

- 3D Visualization:

The CAD software enables the creation of a 3D representation of the jewelry. The specialty of this 3D representation is that it enables the designer to visualize the gemstone jewelry piece from multiple angles. This process is important because it allows the detection and correction of various errors in the jewelry design, and it fixes the flaws of the design before the production even begins.

- Adjustments and Refinements

In this stage of jewelry CAD design, adjustments are made and the CAD design is refined. Designers experiment with various elements, for instance, the choice of material, placement of gemstone, and features of the design – and they make sure that both – beauty and as well as functionality are prioritized.

- Exporting CAD Files

After all of the adjustments are made and all flaws of the design are removed, the design is finalized, and it is exported to a file format that is compatible with CAM (Computer-Aided Manufacturing) systems. These files are typically in STL or OBJ file formats.

- Production Process via CAM System

The CAD model that is exported into STL or OBJ file format is transferred to CAM software. The CAM system utilizes different methods like 3D printing or CNC machining for the creation of physical models from the digital design. Often, the CAM system produces resin or wax models of the jewelry presented to the client. Many manufacturers use resin or wax printing technologies within the CAM system to produce wax models used in the casting process.

Jewelry Making Process After Completion of Jewelry CAD Design

After the jewelry CAD design is used in making physical models of wax or resin, the next stage in the jewelry-making process is the casting process. In this process, wax models that are generated with the help of CAM systems are utilized in lost wax casting. The jewelry-making process after the jewelry CAD design is completed in two stages – lost wax casting and final assembly. Below is a brief explanation of these two stages:

- Lost Wax Casting:

In lost wax casting, the wax model is encased inside a material (which is a chemical) that hardens around the model. After the chemical is set, solidifying around the model, the wax is melted away, leaving a cavity in the shape of the original design created via CAD software.

Within this cavity, molten precious metal, such as sterling silver, gold, or platinum, is poured and allowed to cool. Once this molten metal cools, the jewelry produced by casting is revealed.

- Final Assembly and Finishing:

In this stage of jewelry jewelry-making process, the final piece produced through casting is refined by the jeweler – imperfections are removed, gemstones are set, and additional decorative processes, like enameling, are done.

Benefits of Jewelry CAD Design

The integration of jewelry CAD design has many benefits, and the use of CAD has not only enhanced the jewelry-making process's efficiency but also skyrocketed customer satisfaction. Below are some of the benefits of CAD in jewelry design:

Enhanced Visualization

3D Rendering: The CAD software enables designers to create a highly detailed 3D model of the gemstone jewelry piece. This 3D model is a realistic representation of the final jewelry piece. Thus, the 3D model created via 3D rendering allows both the designer as well as the client to visualize the jewelry piece with clarity, and envision how the jewelry piece will look in real life.

Client Presentation: High-quality 3D models can be used in presentations with the client, and through these presentations, the client easily understands the design concept. Because the client can visually see the jewelry, the client gets satisfied, leading to quicker approvals.

Customization

Personalized Designs: CAD allows the clients to customize the jewelry according to their desires, and personalize it based on their taste. As soon as the designer understands what the client wants, he can quickly incorporate the elements the client has requested, like custom engravings, a specific gemstone, or a unique shape.

Flexibility in Design Changes: If the client asks for changes in the jewelry's design, the designer can easily modify the 3D model through CAD software to implement what the client requested without starting from scratch.

Time Efficiency

Streamlined Workflow: The traditional hand-drawing and sketching process is quite time-consuming compared to digital modeling. The creation of 3D models in jewelry CAD design speeds up the whole process of designing. Also, since designers can create multiple variations of designs quickly, they can explore different ideas without wasting too much time.

Reduced Production Time: Once the design is finalized as a CAD file, it can be translated into manufacturing instructions for the CAM machine. This seamless linking of CAD files and CAM system is more time efficient than manual drafting and prototyping.

Precision and Accuracy:

Precise Measurements: The CAD software enables the designer to have precise measurements within the 3D model that you cannot get manually. The accuracy in measurements ensures that the design meets quality standards.

Error Reduction: Because the whole process of jewelry CAD design is digital, it minimizes the risk of human errors that can occur during sketching and manual drafting.

Final Thoughts on Gemstone Jewelry-Making Process

Did you like this extensive read on jewelry CAD design? We hope that now, you know what the process of jewelry CAD design actually is. Designing via CAD is an important part of the jewelry manufacturing process. Technically, CAD will only grow and improve with time, and in this age of AI, we don't know what the future holds for us. Maybe, in the future, some AI system will be integrated into CAD software to make beautiful and unimaginable jewelry designs.

Even the current CAD design technology is revolutionary – 100 years ago, who could imagine that the jewelry industry would have people working on computers would ease the jewelry making processes? Today CAD software is used in making various jewelry designs, which can be of anything – be it a gemstone pendant, gemstone ring, or any other gemstone jewelry.

Having said that, if you are a jewelry retailer and wish to purchase wholesale gemstone jewelry produced through casting, you can purchase it from Rananjay Exports, India's biggest wholesale gemstone jewelry manufacturer and supplier. At Rananjay Exports, you can order all types of jewelry, curated in 925 sterling silver, produced via casting. Other than casting, we sell other handmade jewelry, including sea life collection, birthstone jewelry, chakra jewelry, and so on. Browse Rananjay's website and order jewelry available in more than 250+ natural and ethically sourced gemstones.