Cart0Item(s)

You have no items in your shopping cart.

THE INSIDE STORY

Rananjay Exports has always been manufacturing the gemstone studded jewelry that is loved by jewelry wearers and gemstone enthusiasts worldwide.

The jewelry that bears the signature of Rananjay Exports is preferred by the jewelry resellers for a reason. With our intricate processes that are carried out by our expert and experienced artisans, we create the most unique jewels. Our different departments are responsible for bringing our jewelry a step closer to becoming the inevitable part of your collections works in harmony with proper synchronization of work. This makes sure that the order is received by you within the time committed by us.

When you place an order with us, this is what happens before it reaches you.

SEPARATION OF EACH JEWEL FROM TREE

To create each jewel that reaches your collections, we need the raw materials obtained from nature. These majorly include the gemstones and the metals obtained from the earth's depths by mining. We make sure that whatever raw material is sourced for our jewelry is extracted most ethically. We like being honest and practical here. When we say ethical sourcing, it does not mean that we assure zero damage to the environment but as minimum harm as possible. We also take care of all the rules and norms that need to be followed. We take responsibility for the local people who are affected, and they are given due compensation. Also, most of our raw materials are procured from the miners who take proper measures to ensure the mined land does not remain barren for long.

GEMSTONE MANUFACTURING

We are responsible for manufacturing most of the gemstones that we use in our jewelry in our facility. When the raw rocks are sourced, the cutting, polishing, and finishing are done in our facility to make these stone gemstones. Most of the gemstones used in the jewelry are manufactured by our experienced artisans under expert supervision that keep their quality a little above the industry standards. Every activity involved in the creation of our stunning silver jewelry is carried out under one roof. This gives us the confidence and satisfaction to provide the best quality and authentic jewels to our valuable members.

HANDMADE JEWELRY RANGE

Our handmade jewelry range consists of beautiful statement jewels that show our artisans' expertise in each piece. As the name suggests, these jewels are created manually right from the gemstone selection to set them into the sterling silver setting. This also includes assembling the pieces to bring one jewelry item into existence. It requires the experience to select the right size and variety of the gemstones and set them in the sterling silver setting. It has to be done with such perfection that it glorifies your beautiful collections and is loved by your clients. We make sure that each piece from our handmade range does justice to our quality and standards. For this, they are also checked by our quality check department before being displayed.

DESIGN MOULD

A silicone, rubber, or metal mold is prepared with the impression of the CAD design. The mold is such that the top of the design is on one piece of it, and the bottom half is on the other one. When both the pieces are kept on one another, then it completes the design. After assembling, it looks like a cuboid with a hole at one side.

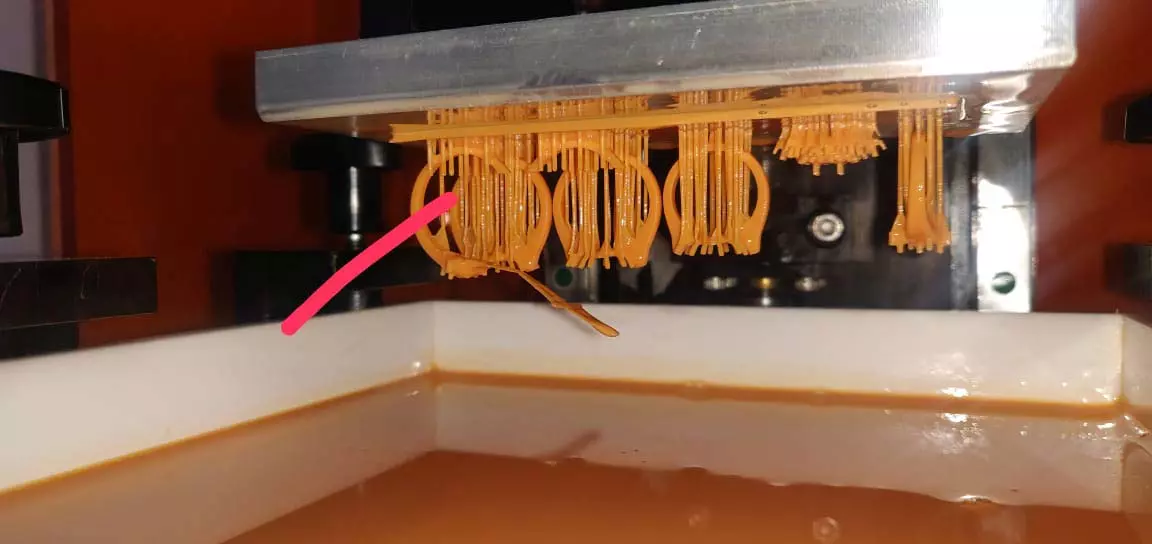

INDUSTRIAL WAX DESIGN

Industrial wax is injected into the mold through the hole, which fills the crevices of the design, thus creating a wax design. Multiple pieces of the same designs are made based on the requirement.

WAX DESIGN TREE

All the wax pieces are assembled around a wax rod, making the whole structure appear like a pine tree. This helps in keeping the record of the jewels of one order and one design sorted.

P.O.P. MOULD

The wax tree is inserted in a flask which is then put into the investment machine. This machine mixes the industrial P.O.P. powder with water in a pre-defined ratio and removing the air bubbles. This paste is then poured into the flask, which covers the wax tree completely. The flask is then shifted to the furnace, which heats it at 700 degrees for 12 hours. This melts away the industrial wax from the flask, thus leaving the tree mold of P.O.P.

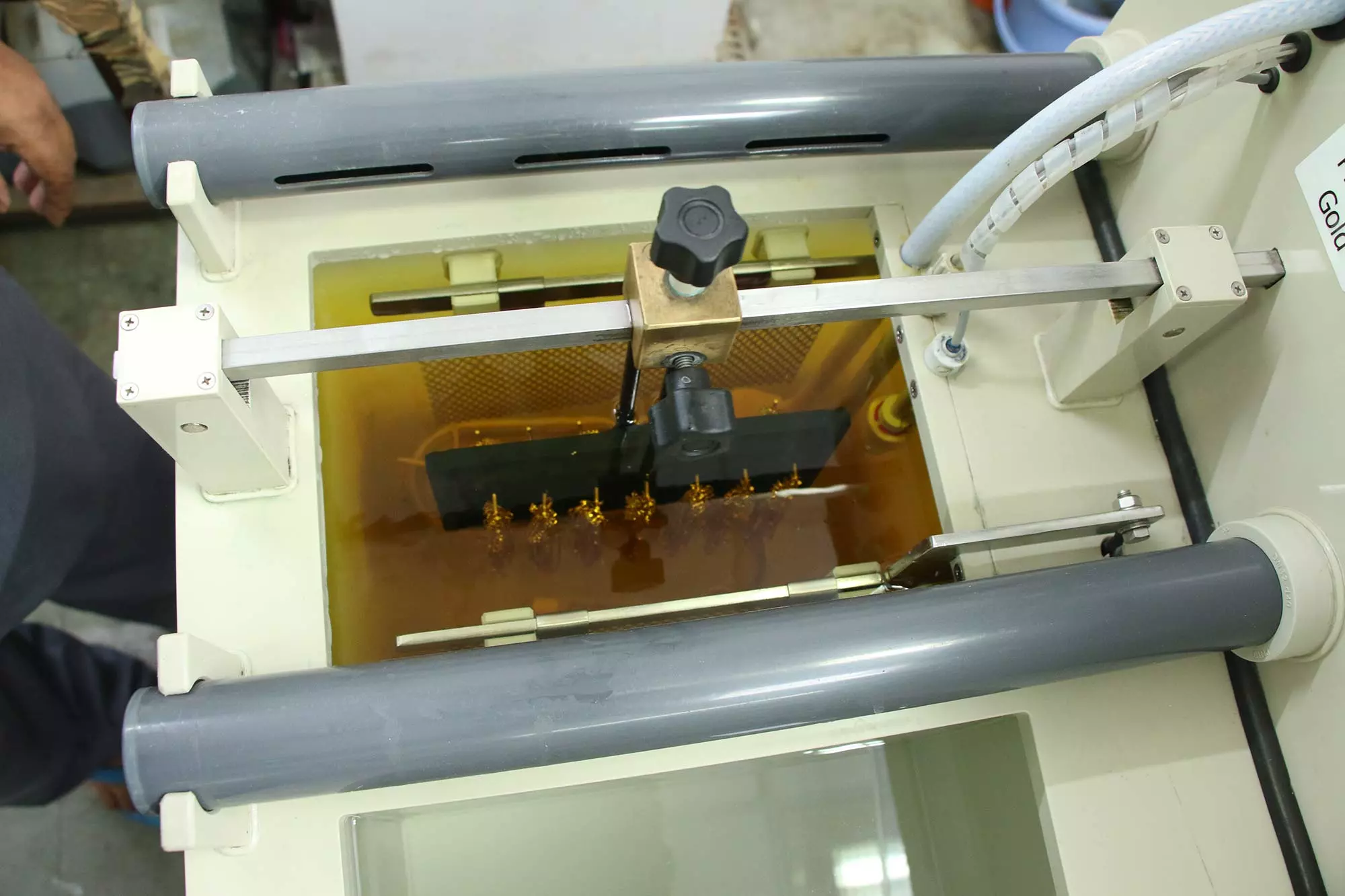

METAL CASTING

The P.O.P. tree mold is set up in the casting machine with the metal at their designated places. The device conceals itself in an air-tight fashion. Then it melts the metal at 1000 degrees and pours it into the P.O.P. tree mold. This happens inside the casting machine after the required codes are given to it.

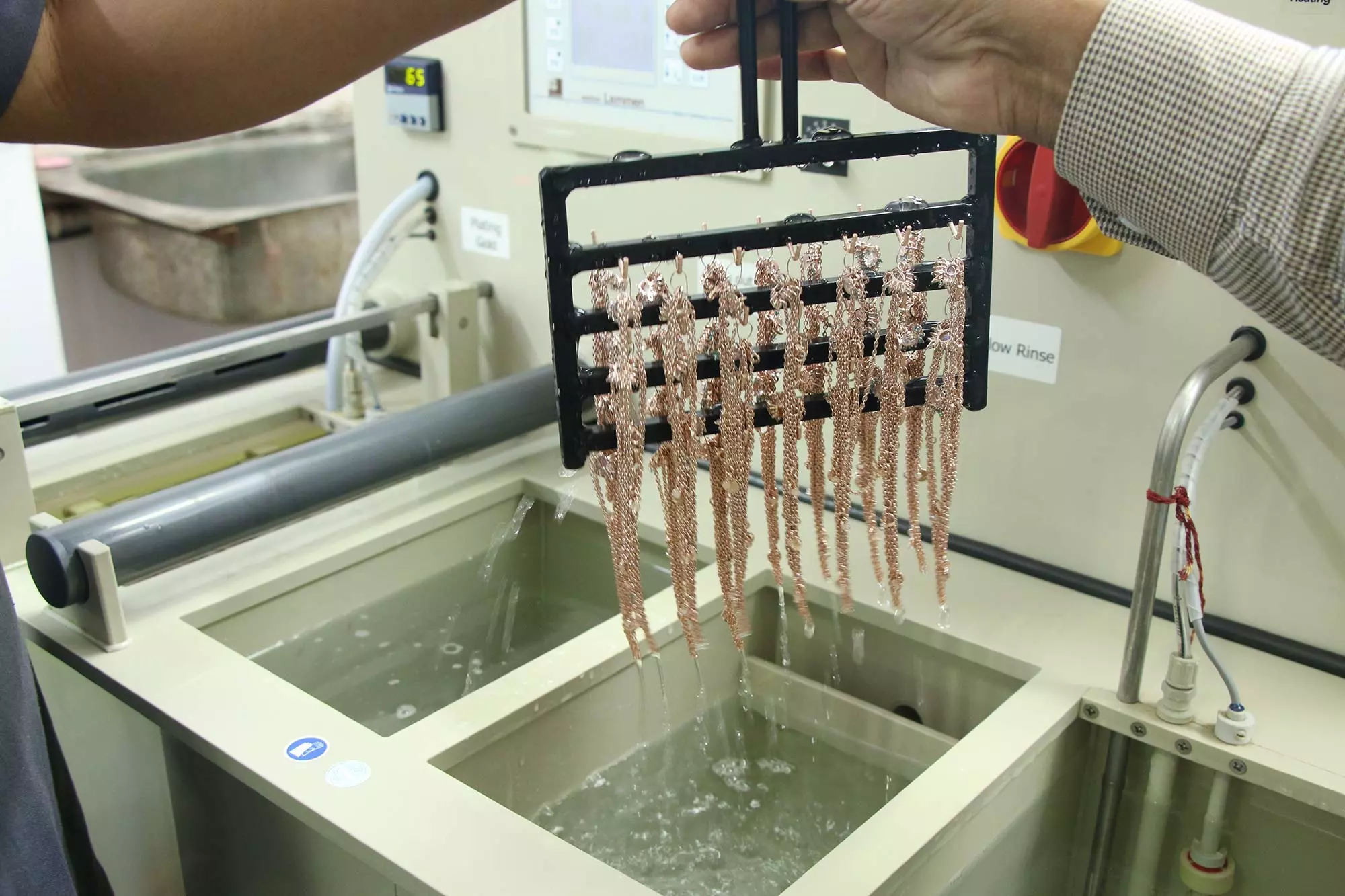

JETTING MACHINE

The hot and burning flask with the metal tree inside is very carefully removed from the casting machine and kept in the jetting machine, where an experienced person cools it down under running water. This cleans off the P.O.P. from the flask and leaves the metal tree, the replica of the wax tree created in the fourth step.

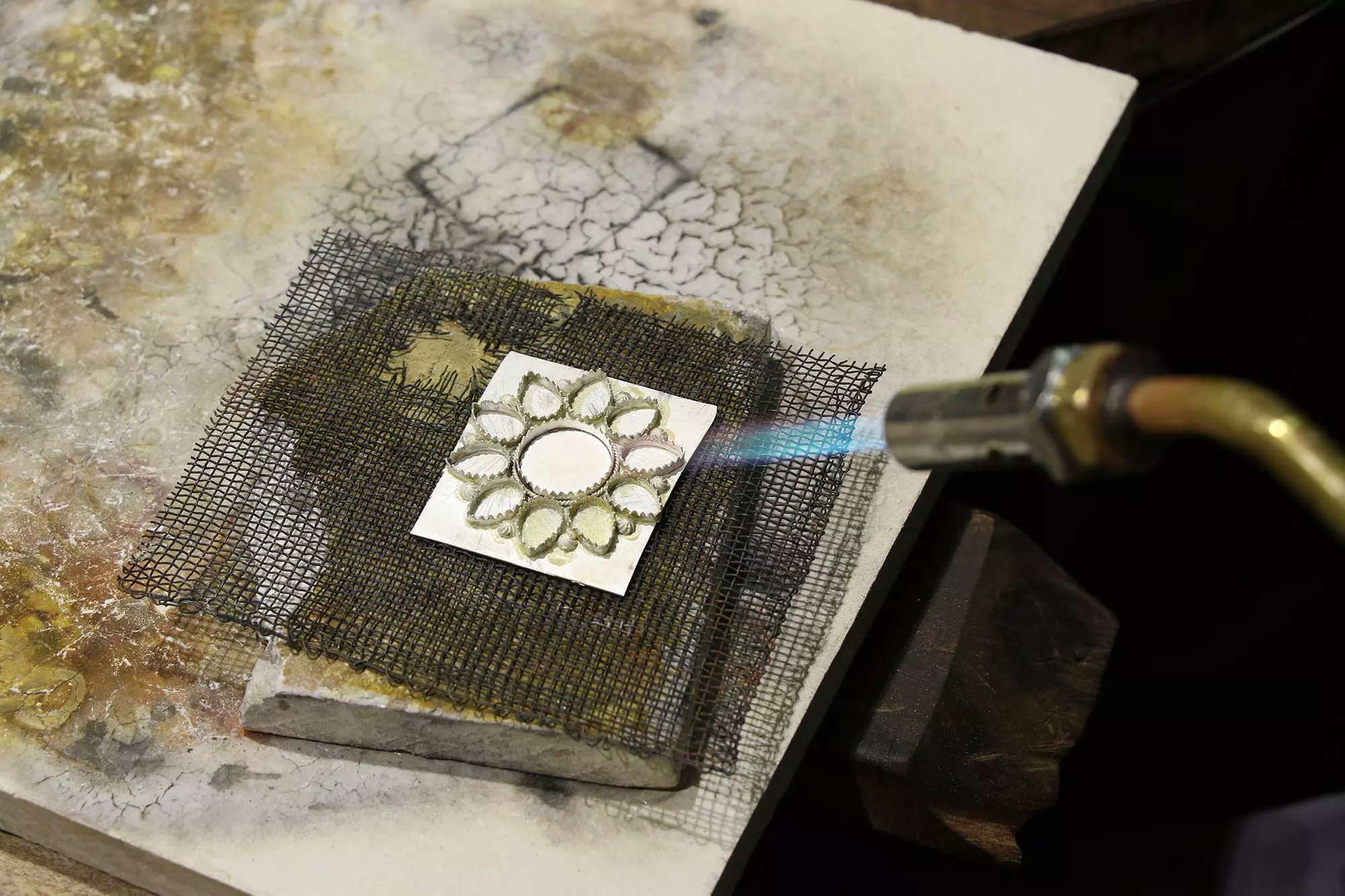

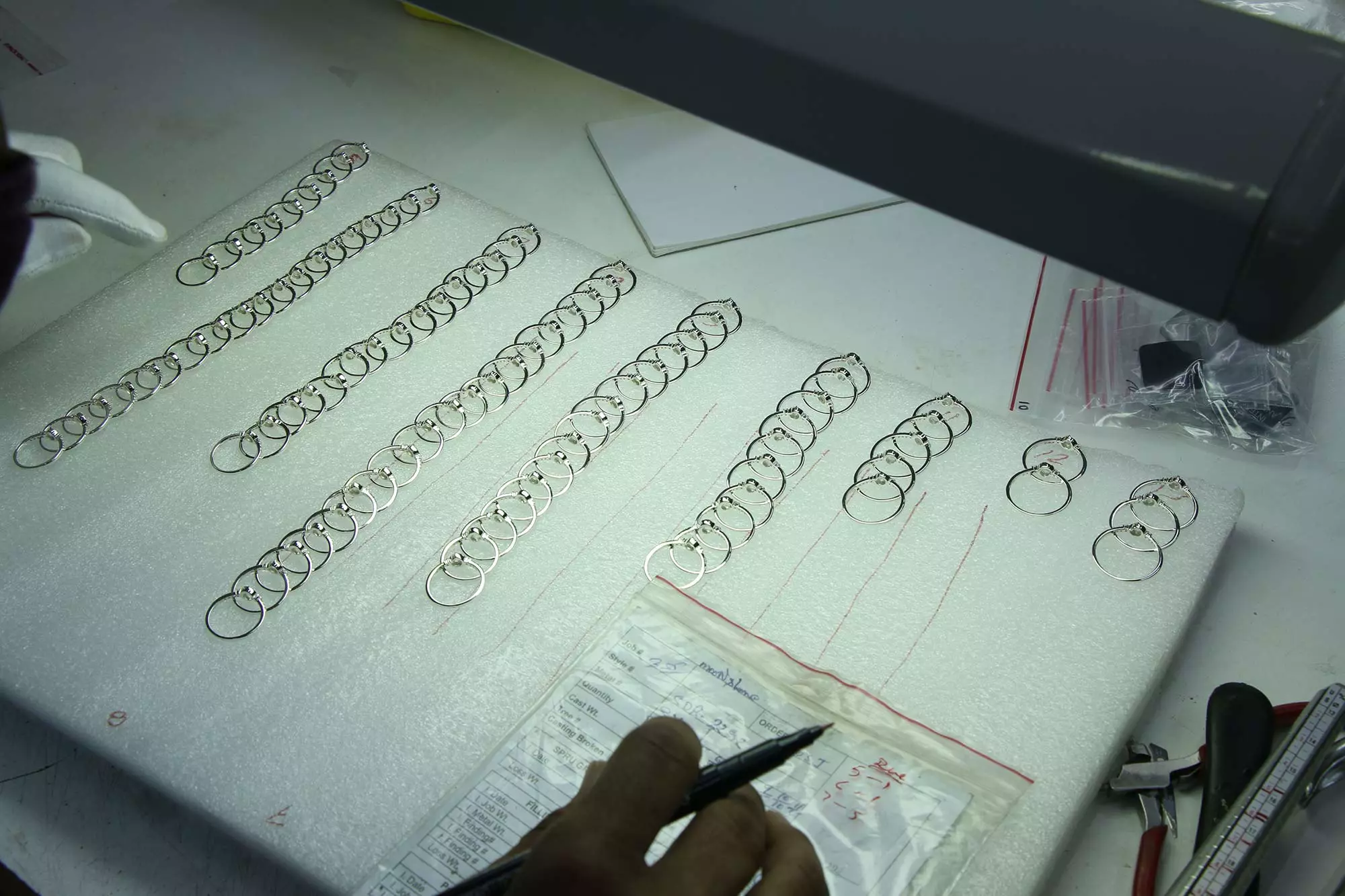

SEPARATION OF EACH JEWEL FROM TREE

Every piece is cut from the metal tree to separate it from the rod and get the identical metal setting. These settings are not perfect and contain flaws and imperfections.

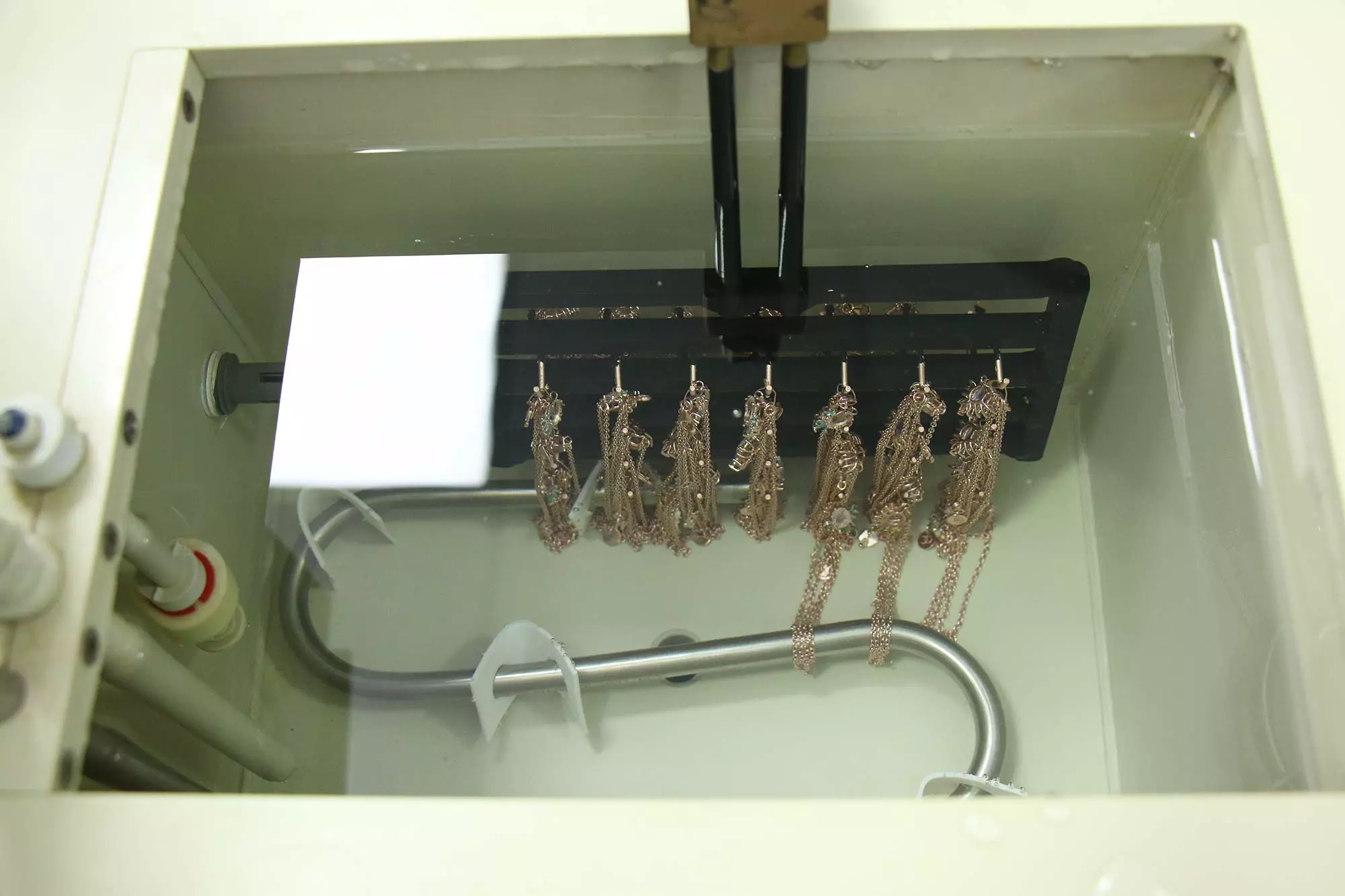

VERMEIL AND GEMSTONE SETTING

The vermeil is done on the metal settings based on the requirements and set standards that make our jewels immune to damage through scratching. After this, the gemstone is put into the silver setting based on the design. This is done manually with the latest tools by our experienced artisans with extreme attention to detail.

QUALITY CHECK

The jewels are given a final finishing touch and sent to our quality check department. Here every single jewelry item is checked by our experts based on the standard industry parameters. And we are proud to say that there are less than 1% rejections which do not occur in every lot.

PACKING AND SHIPPING

The final jewels are then nicely packed and shipped to the desired location. And we make sure these jewels reach you within our committed time to be included in your beautiful collections.This is how each jewel of our catalog jewelry range that bears the tag of Rananjay Exports comes into being.

OUR SUPPORT TO OUR ARTISANS DURING THESE TOUGH TIMES

COVID-19 hit the world like nobody ever expected. No country, business, or individual was prepared for the effects it brought with it. During these challenging times, we are highly supportive of the well-being of our craftsmen, artisans, and all our employees. We take the responsibility of food and transportation for the local employees and provide the additional accommodation facility to the ones coming from their hometowns. We understand how difficult it is for these craftsmen to find employment. We had welcomed each of them with open arms. We cared for their needs when they remained quarantined after returning from their local place to our facility. We never laid off a single employee from any department because of the market conditions. We provided complete salaries and wages to everyone who contributes in some manner to make Rananjay Exports what it is today. We will never let anyone associated with us suffer while we are here. We value our employees so much that we are willing to go that extra mile for their well-being, and we don't mind doing that. We believe in the employee first approach because an employee's happiness and satisfaction are shown in the brilliant jewelry items. Any person who gets associated with Rananjay Exports is promised a lifestyle that he deserves. Once a part of Rananjay Exports always remains inevitable part no matter what. We are the organization that always stands for its members. THEIR SATISFACTION COMPLETES US!

OUR SOCIAL RESPONSIBILITY

When we take from society to keep our business running to continue manufacturing the jewels for your collections, we must give something back. And we are doing it most organically. With every order we receive, we plant one tree in association with 'One Tree Planted.' We all want to make this world a cleaner and greener place to live in, and if we can contribute to this, then what can be better. Along with making an impact on a larger scale, we also take small steps towards bettering the future of our workers' families, especially their daughters. We take complete responsibility for a girl child's primary and secondary education along with the basic amenities. This is a voluntary scheme open for our artisans. The happiness we see on their faces when their daughters graduate and become employable is otherworldly.

PROPER DISPOSAL OF WASTE

Another thing that we consider as our responsibility is the proper disposal of waste. While creating jewelry, the byproducts cannot be avoided, but what can be avoided is the harm it does to nature. We make sure that the waste emitted from our production activities is adequately treated before disposal. We can never provide the jewelry to the world that makes this world a toxic place to live in. Our waste footprint is lower than the industry standards, and we are proud of that.